Delivering exceptional value at every stage of the refining process

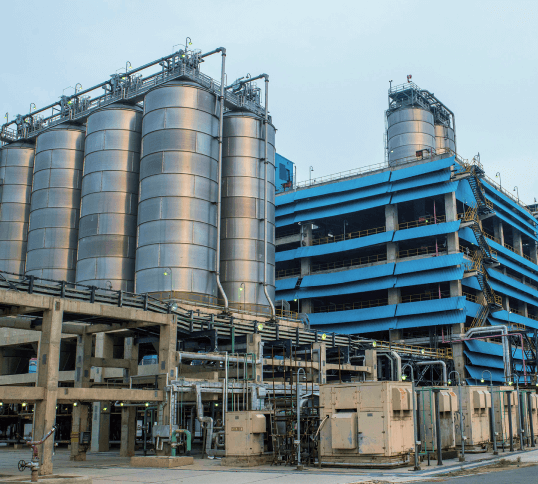

Meeting the growing global energy demands requires operations that function seamlessly and efficiently across all levels. At HMEL, we’ve made this a reality with the Guru Gobind Singh Refinery (GGSR), an Integrated Refinery-Petchem Complex built with a total investment of USD 8 billion. This strategic convergence of refinery and petrochemical operations positions HMEL as a leader in the dynamic world of energy by maximising resource utilisation, enhancing product offerings, and significantly reducing our environmental footprint. Our Zero Liquid Discharge Refinery and Petrochemical complex with an advanced Effluent Treatment Plant leverage cutting edge technology, continuously optimising performance and profitability while maintaining the highest safety and environmental standards.

Our state-of-the-art refinery is an environment-friendly, energy-efficient facility with a processing capacity of 11.3 MMTPA. As one of Punjab’s largest investments, GGSR caters to the demand-driven market in Northern India, setting a new benchmark in clean energy production.

We have established a world-class petrochemical plant designed to meet India’s rapidly growing demand for polymers. Our facility features India’s largest dual-feed cracker (1200 KTPA), along with multiple advanced units dedicated to producing polypropylene and polyethylene.

Unit-specific teams focus on identifying and mitigating operational risks through brainstorming sessions.

Regular safety talks by executives/ contractor supervisors in local safety committee meetings, safety briefings, and IIF area meetings initiated.

VR models based training on operations such as Extruder, DDSV, Coke Drum, and PP Bagging, and Interactive safety modules.

Manpower training and validation using Operator Training Simulator (OTS).

Table Top Drills and Mock tagging activity to enhance manpower readiness for Emergency Response and Incident Management.

Empowering safety through on-ground leadership by inspiring safe practices and encouraging action against unsafe work conditions.

GGSR was conceived with an innovative mindset and global expertise to deliver world-class performance. From its inception, the refinery has been a hub of digital transformation, incorporating advanced systems like Manufacturing Execution System (MES), System Analysis and Programme Development, Operator Training Simulator and Corrosion and Inspection Management Systems. Our minimum manning philosophy and cross-training enhance workforce adaptability, while our advanced integration framework enables informed decision-making, keeping us at the forefront of the energy sector.